Laser Cut Metal in Martial Arts

For an exciting example of the uses of laser cut metals we can look to martial arts and the use of traditional weaponry in practicing these ancient techniques. Seaholme specialise in making such martial arts equipment, just as we at Yorkshire Profiles specialise in laser cutting and metal fabrication.

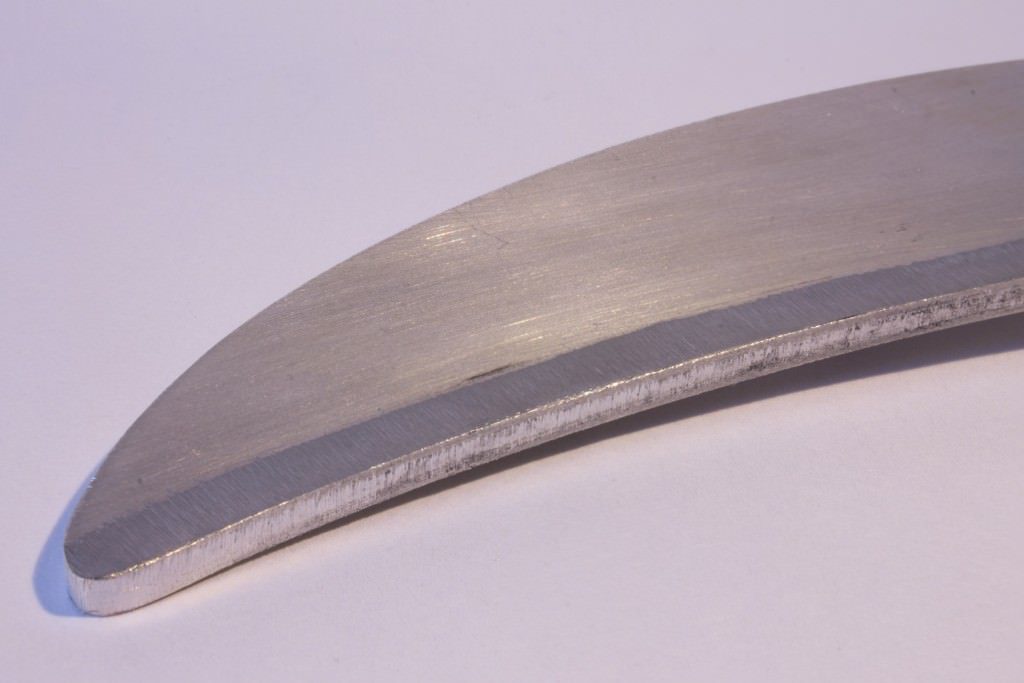

The Kama is a traditional Filipino and Japanese farming tool that looks like a smaller version of a sickle. Its traditional use was to reap crops, but in its sharpened form it has also been used in a weapon. With a blade made from steel or aluminium and a handle of ash, oak, maple or walnut, this tool is an outstanding combination of laser cut metal, carpentry and fabrication of metal to wood using countersunk rivets.

Made for neither farming nor war, the Kama at Seaholme are used as an aid to developing technique and physical strength in the practice of Okinawan Kobudo, a sister in martial arts to the wider known Karate. These Kama’s were specially designed by Seaholme to showcase quality materials and a high quality finish, and are made in the UK, producing a long lasting product with no sharp points or edges for the purpose of practice in Kobudo with a truly traditional and high specification piece of martial arts equipment.

So, you may ask how such traditional equipment could possibly benefit from laser cutting technology. The answer is simple: precision. Our F1 laser cuts with tolerances of less than 1mm and with finishing techniques thrown in, we can grind and buff any metal to a clean and burr free finish. This produces a high quality product to specific design requirements over and over again.

Modified for safety, the blade design of these Kama is based on the traditional tool and can be made from either aluminium or steel at 4mm thickness. The price differs, of course, because of the different properties of the metals.

Aluminium is softer and lighter than steel, weighing only 94g in the Seaholme Kama – that’s 3 times lighter than the steel blade which weighs 265g! Being corrosion resistant is great for the aluminium blade, but it can be prone to scratches. In steel the Kama has a traditional “heft” for use in practicing martial arts, but it is prone to corrosion through gradually oxidising. However, the steel can be hardened to provide corrosion resistance and is better for the more experienced martial artist.

In martial arts practice like those with equipment provided by Seaholme, the blades are blunt but specifically designed for purpose. And that’s where we come in. These blades are produced for Seaholme using our laser cutting technology, the Amada F1. A design is created, programmed by our CAD technicians, cut using our laser and finished using processes such as rumbling or grinding before being sent to Seaholme to be turned into the finished product you see pictured here.

Remember, however bespoke your requirements, get in touch with us at Yorkshire Profiles for any laser cutting or fabrication needs and we’ll be happy to help!